SLM and DMLS 3D Printing Services

ON-DEMAND SLM & DMLS 3D Printing Services FROM Graphscape 3D PRINTING

Graphscape 3D Printing, an ISO 9001-2015 certified company, delivers specialized SLM & DMLS 3D Printing Services solutions across various industries. As metal 3D printing gains popularity, we actively adopt advanced DMLS and SLM technologies to address complex manufacturing needs. With our vast experience in additive manufacturing, we produce industry-grade components quickly and with top-notch quality. Whether you’re exploring selective laser or direct metal printing, our team is ready to guide you every step of the way.

WHAT IS SELECTIVE LASER MELTING (SLM)

Selective Laser Melting (SLM) 3D printing offers an advanced approach to fabricating metal components. Unlike basic fusing techniques, SLM completely melts each metal powder layer using a high-powered laser, which creates strong and durable parts. This technology works seamlessly with metals such as aluminum, cobalt chrome, titanium, and stainless steel. During the process, each layer gets heated beyond its melting point, enabling efficient and precise manufacturing.

How does SLM 3D printing technology work

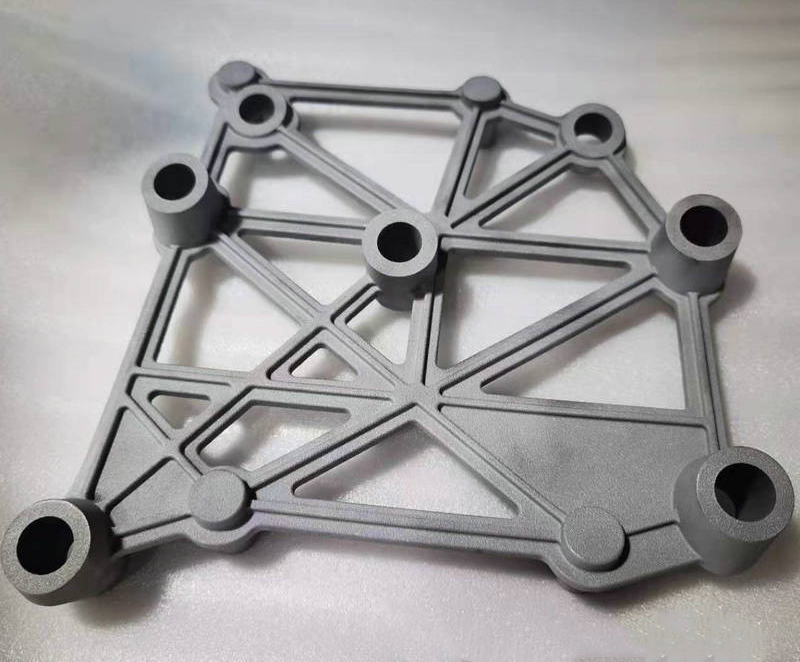

In SLM 3D printing, materials build up layer by layer through precise computer control. A high-power laser melts the metallic powders entirely, allowing them to solidify and bond with previous layers as they cool. Consequently, this method supports the creation of complex geometries, such as hollow or porous structures. Due to its precision, SLM is ideal for aerospace, dental, jewelry, and medical implant manufacturing.

What is Direct Metal Laser Sintering

Direct Metal Laser Sintering (DMLS) represents an energy-efficient alternative in metal 3D printing. Instead of fully melting metal powder like SLM, DMLS partially sinters the powder, minimizing energy use and reducing operational costs. It utilizes extremely fine powder particles, often under 10 microns, composed of elemental metals or alloys. Moreover, DMLS frequently reduces the need for post-processing, streamlining production workflows.

How does the Direct Metal Laser Sintering (DMLS) process work

DMLS begins by spreading a layer of metal powder onto the build platform. Next, a high-powered laser fuses this powder to form a solid cross-section of the part. This process repeats layer by layer until the final object takes shape. Widely used in industries like automotive and manufacturing, DMLS supports the efficient creation of intricate metal parts. At Graphscape 3D Printing, we use state-of-the-art DMLS machines to deliver quality products rapidly and reliably.

ADVANTAGES OF SLM AND DMLS

Mass Customisation:

Manufacturers now enjoy greater flexibility in designing tailored products without relying on traditional tooling and dies. This shift enables quick transitions to large-scale production without design constraints.

Monolithic Design:

Using DMLS, manufacturers can effortlessly build intricate parts in one cohesive piece, eliminating the need for joints or assembly. This approach accelerates production and enhances structural durability.

Improved Functional Performance:

With DMLS and SLM, manufacturers consistently produce parts that offer exceptional mechanical performance. These techniques allow for crafting detailed components with greater strength than those made via traditional methods.

Better Weight Optimisation:

When optimal weight distribution matters, manufacturers turn to DMLS and SLM. These methods provide unmatched precision and geometric flexibility, ensuring lightweight yet durable parts for demanding applications.

Ready to Get Started? Let's Build Something Great Together!

Have a project in mind or need expert guidance? We’re just a message away. Click below to connect with our team — we’re here to help bring your vision to life with the right solutions tailored for your business.