SLA

What is SLA 3D Printing?

SLA (Stereolithography) uses a laser to solidify liquid resin, creating precise 3D models layer by layer. This technique is known for its high resolution, which makes it ideal for industries like engineering, medical, and jewelry, where fine details and accuracy are essential.

In addition, SLA is the perfect solution for rapid prototyping and low-volume manufacturing. This method ensures a faster turnaround time, lowering production costs while maintaining quality. The laser works according to the design’s specifications, solidifying the resin in exact layers to form the final model.

Applications of SLA 3D Printing

Graphscape 3D specializes in SLA 3D printing, providing swift and high-precision prototypes. Our services include the creation of functional parts, casting patterns, and mechanical components. SLA’s versatility allows us to print parts in various industries, and we can ship parts in just one day.

Here are the key applications of SLA printing:

Prototyping: Quickly create models for design validation and testing.

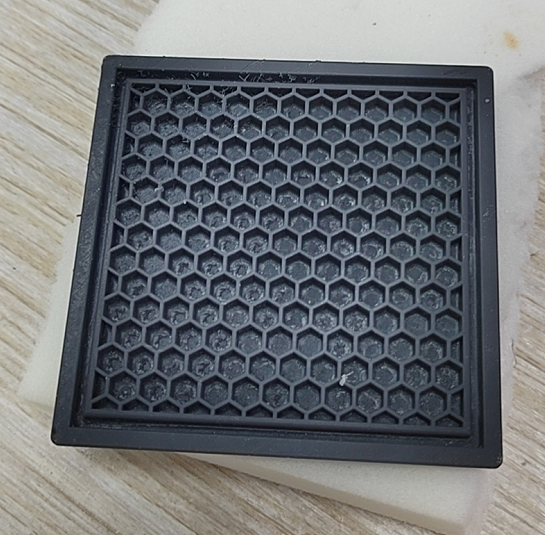

Tooling, Jigs, and Fixtures: Build durable components for manufacturing processes.

Casting Patterns: Generate precision molds for casting.

Custom Parts: Design and produce parts tailored to specific requirements.

Why Choose SLA 3D Printing?

SLA is a popular choice for industries demanding accuracy and smooth finishes. Manufacturers, medical professionals, and jewelers prefer it for its ability to create intricate and durable parts.

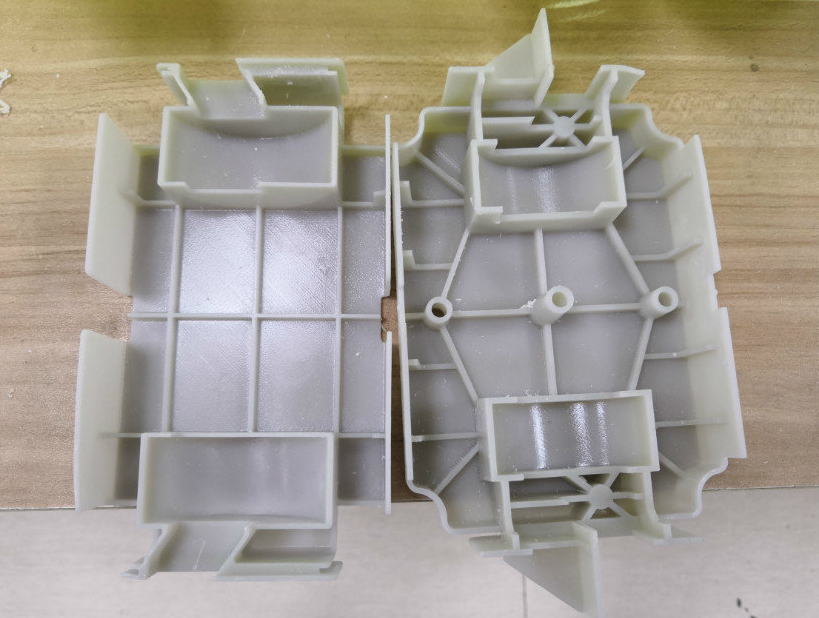

The SLA process begins with a 3D CAD file, which the SLA printer slices into layers. The laser then cures the resin layer by layer, creating the desired part. This technology can create fine details, such as thin walls and delicate features, which other 3D printing methods might struggle with.

How Does SLA 3D Printing Work?

Designing:

Create a 3D CAD file using software like SolidWorks or SelfCAD. Export the design in OBJ or STL format, and slice it into layers. The sliced design is then ready to be printed.

Printing:

Once the setup is complete, the SLA printer solidifies the resin layer by layer using a UV laser. Many printers use automatic cartridge systems to refill the resin during the process, ensuring continuous printing without interruptions.

Post-Processing:

After printing, the part is rinsed with isopropyl alcohol (IPA) to remove excess resin. Post-curing under UV light ensures greater strength and stability. Finally, engineers remove any support structures, leaving the finished part.

SLA 3D Printing in Various Industries

SLA technology benefits many industries by offering precise, reliable, and cost-effective solutions. Key industries using SLA 3D printing include:

Manufacturing: For rapid prototyping and short-run production.

Medical: To create prosthetics, implants, and dental devices.

Jewelry: To produce fine and customizable jewelry pieces.

Aerospace: For manufacturing lightweight, high-precision components.

Automotive: To create durable vehicle parts and prototypes.

Ready to Get Started? Let's Build Something Great Together!

Have a project in mind or need expert guidance? We’re just a message away. Click below to connect with our team — we’re here to help bring your vision to life with the right solutions tailored for your business.