PolyJet 3D Printing

POLYJET 3D PRINTING

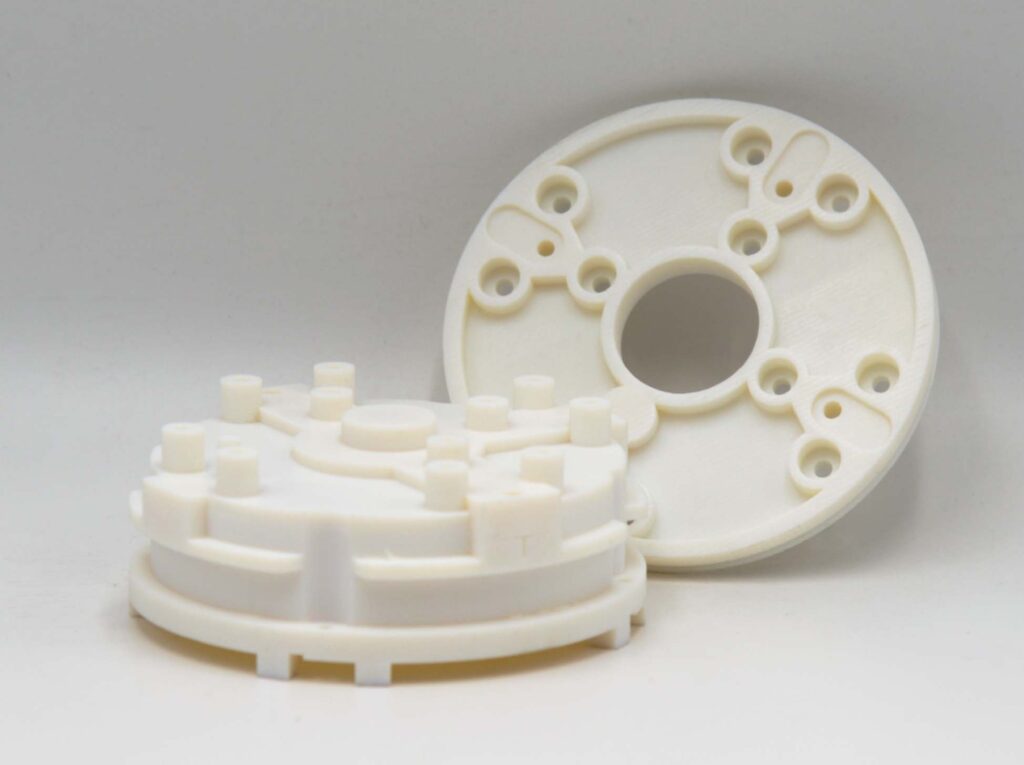

PolyJet 3D Printing speeds ahead as the fastest additive manufacturing technology, producing high-definition, smooth, and precise parts. Engineers appreciate how it mirrors digital-file mechanics to create cured objects with minimal or no extra tooling. Moreover, this method accommodates soft, rigid, and colorful components—complete with intricate geometries—by jetting multiple material droplets in each build. In addition, a UV lamp instantly cures every thin photopolymer layer right after deposition. As a result, PolyJet excels at printing functional prototypes and end-use products for medical, dental, consumer-goods, eyeglass, and jewelry applications. Furthermore, aerospace and automotive teams already leverage its capabilities to accelerate development cycles.

3D printing PROCESS

In this process, printers spray tiny droplets of liquid photopolymer onto the build platform and cure them immediately with ultraviolet light. Consequently, you can combine different materials within a single print and achieve finely detailed, multi-colored surfaces. Also, finishing and painting take only a few straightforward steps. Beyond that, these durable parts stand up to drilling or tapping tasks. Finally, rapid slicing and precise layer placement deliver faster turnaround times compared to traditional methods—and they require almost no post-processing before use.

IDEAL APPLICATIONS

Ideal for rapid prototyping and small-batch runs, PolyJet shines when projects demand multiple materials in one part. Designers across aerospace, automotive, electronics, and medical fields rely on its pinpoint accuracy and fine detail. As a result, manufacturers trust it for applications such as:

Prototyping

Dental models

Medical devices

Consumer-goods samples

POLYJET 3D PRINTING SERVICE

At Graphscape 3D, we harness advanced machines to craft intricate solid parts and lifelike prototypes in record time. When your project calls for realistic models—complete with varied materials, vibrant colors, and razor-sharp detail—we deliver efficient, end-to-end solutions. Additionally, our PolyJet service guarantees superior surface finish, exceptional strength, and dimensional accuracy. We also stock a broad palette of materials, from transparent resins to flexible elastomers, so you get exactly what your design requires. Whether you need a one-off prototype or a small production run, our team stands ready to support you at every stage.

Process

We begin with Pre-Treatment and Materials Handling. First, we load the photopolymer cartridge and prime the inkjet printhead. Then, we clear the build platform of contaminants—often using zeolite powder—to ensure uniform resin distribution.

Next comes Object Printing. Our system jets liquid photopolymer layer by layer, curing each with UV light. This approach lets us combine plastics, rubbers, and even metal-filled resins in one seamless part.

Afterward, we tackle Powder Removal. A built-in vacuum system sucks away all unbound powder, leaving only your printed geometry behind.

Finally, we perform Post-Treatment. We clean and inspect each piece using advanced software to confirm dimensional accuracy. Then, we apply any necessary chemical treatments—such as post-curing—to boost strength and detect imperfections under UV light.

Ready to Get Started? Let's Build Something Great Together!

Have a project in mind or need expert guidance? We’re just a message away. Click below to connect with our team — we’re here to help bring your vision to life with the right solutions tailored for your business.