Laser Cutting

LASER CUTTING SERVICES IN AUSTRALIA

Graphscape 3D offers high-quality laser cutting services across Australia, specializing in precision cutting for prototypes, signs, and architectural models. Moreover, we utilize advanced technology and a team of skilled professionals to deliver accurate results in major cities such as Melbourne, Sydney, Brisbane, and Perth. Whether you’re starting a new project or scaling production, get in touch to ensure reliable, professional service tailored to your needs.

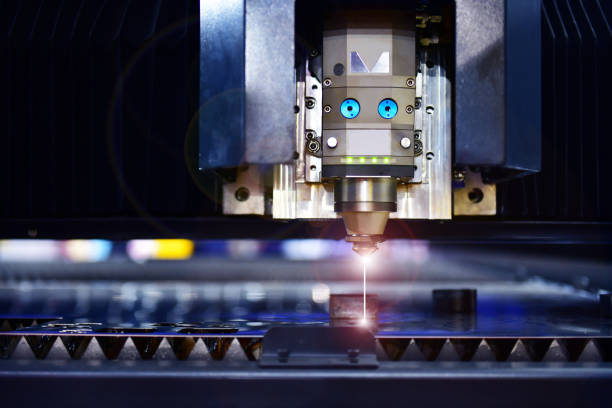

How Does Laser Cutting Work?

Laser cutting involves directing a powerful laser beam to melt and separate materials, while air blows away the molten components. At Graphscape 3D, we primarily use CO₂ lasers, which offer high efficiency and cost-effectiveness. As a result, our laser cutting services are ideal for materials like aluminum and plastic, consistently delivering clean and precise cuts.

LASER CUTTING METHODS

Different laser cutting methods are used depending on the material and project goals. Here are three widely used types:

CO₂ Laser Cutters: Ideal for cutting metals, these provide clean cuts without causing heat damage.

Crystal Laser Cutters: Known for their high precision, making them perfect for detailed metal parts.

Fiber Laser Cutters: Fast and efficient, these are capable of cutting complex shapes with minimal waste.

In addition, our advanced equipment ensures consistent performance across all these techniques.

Laser Cutting Techniques Explained

Laser cutting offers various methods tailored to specific materials and desired outcomes. Below are three common techniques:

Vaporization Cutting: A focused laser beam heats the material to its boiling point, causing it to vaporize. Consequently, this method is perfect for plastics, wood, and foam.

Melting Cutting: This method is less energy-intensive. It melts metals such as aluminum, titanium, and stainless steel, using gas to remove molten material.

Thermal Stress Cracking: Brittle materials like glass and ceramics are heated to create controlled cracks along a narrow cut line. As a result, this technique provides precision for delicate materials.

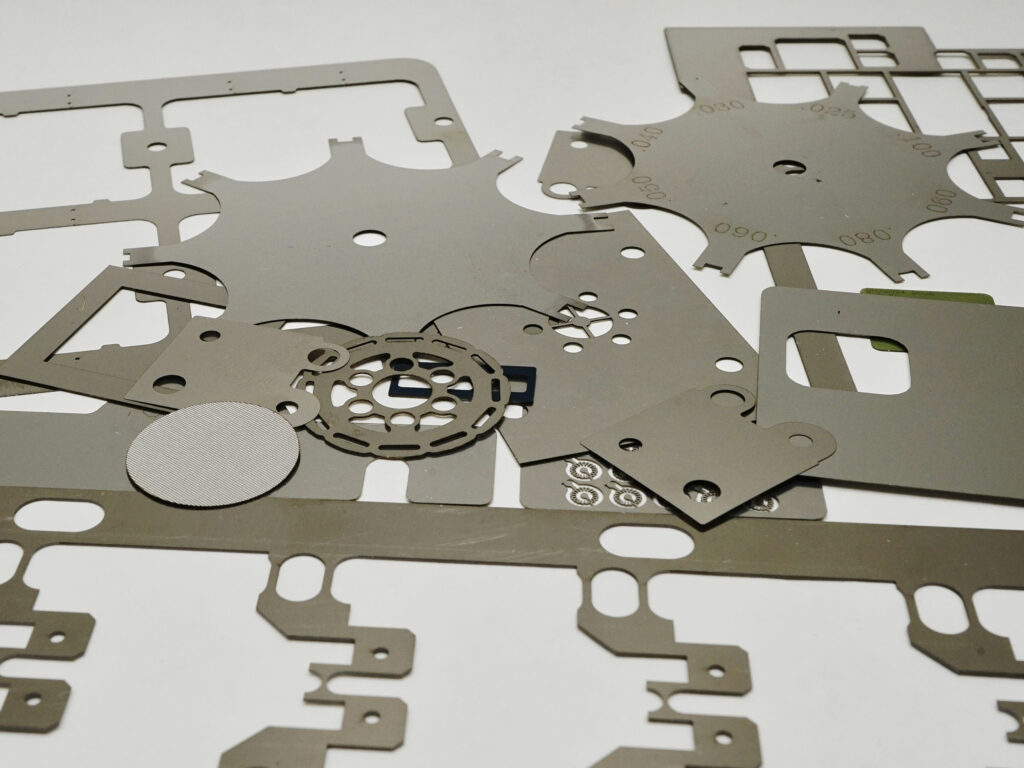

Laser-Compatible Materials

Laser cutting offers versatility across a wide range of materials, making it ideal for intricate designs and detailed cuts.

Here’s a breakdown of commonly used materials:

Plastic Laser Cutting: Often used for jewelry, ornaments, and wall art. Materials include acrylic, ABS, Delrin, HDPE, Kapton tape, Mylar, PETG, Polyethylene, Polypropylene, and Styrene.

Metal Laser Cutting: Perfect for precision cuts in metals such as aluminum, mild steel, and stainless steel.

Because these materials can be melted, burned, or vaporized precisely, they consistently deliver high-quality results.

Ready to Get Started? Let's Build Something Great Together!

Have a project in mind or need expert guidance? We’re just a message away. Click below to connect with our team — we’re here to help bring your vision to life with the right solutions tailored for your business.