FDM 3D Printing Services

What is FDM 3D Printing Services ?

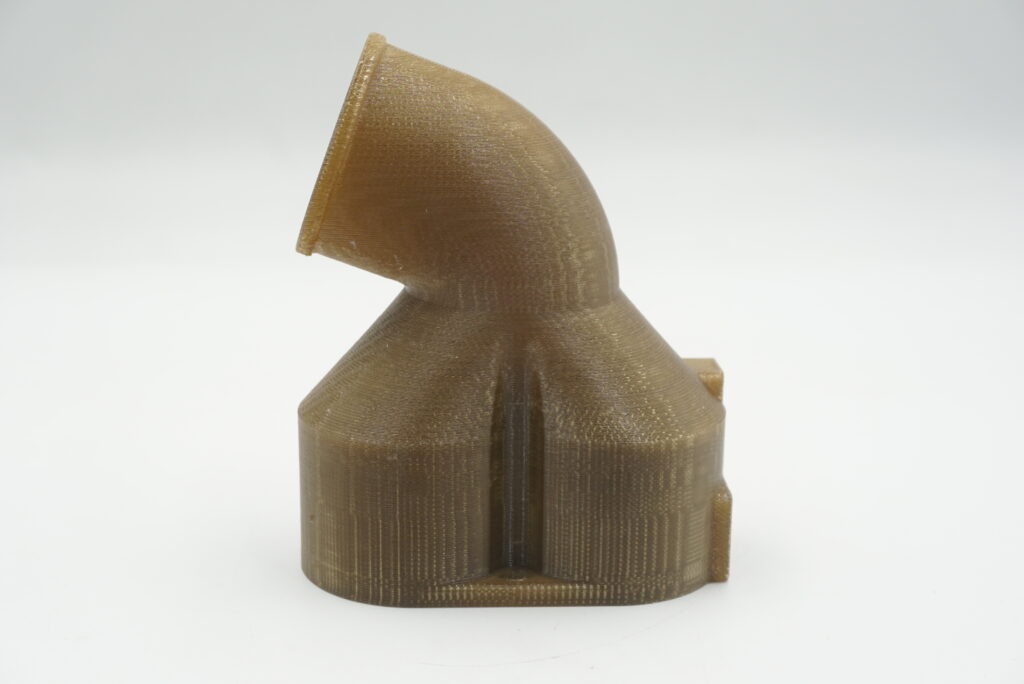

FDM 3D Printing Services is one of the most widely used 3D printing techniques. It works by heating and extruding thermoplastic filament through a nozzle, building objects layer by layer.

Businesses and hobbyists prefer this method because it’s affordable, reliable, and easy to use. Many industries — like automotive, healthcare, and product design — use FDM to quickly develop working prototypes, functional parts, or concept models

How Does FDM Printing Work?

FDM begins with a digital 3D model. After loading the filament spool, the printer heats it until it melts. Then, the nozzle precisely lays down melted plastic in a defined pattern.

As each layer cools, the next one is placed above it. Over time, this builds a strong and structured object. Because of its step-by-step accuracy, the process is ideal for detailed prints.

Moreover, this technology supports various thermoplastics such as PLA, ABS, PETG, and others. You can choose materials based on your project’s needs — flexibility, strength, or resistance.

Why Choose FDM 3D Printing Services?

💰 Affordable Printing

FDM requires minimal setup, making it perfect for cost-effective prototypes. Small businesses and creators use it to save money during product testing.

🌈 Flexible Materials

FDM printers support a wide range of filaments, from biodegradable PLA to industrial-grade nylon. This means you can print objects tailored for specific applications.

🔁 Scalable for Production

You can print a single prototype or scale up for batch production. In either case, the cost remains low and the setup time is quick.

🔧 Functional and Strong

FDM parts can be used in real-world applications. Many engineers create tools, brackets, or fixtures strong enough to handle mechanical stress.

Use Cases for FDM 3D Printing

🧪 Prototyping in Product Development

Design teams use FDM to test shapes, sizes, and functions before final production. It helps reduce time to market and lowers manufacturing errors.

🧰 Manufacturing Tools & Jigs

Companies often print custom jigs and fixtures. These tools improve assembly line efficiency and reduce labor costs.

🏫 Academic & Educational Use

Schools and colleges integrate FDM printers into classrooms. Students learn design, engineering, and creative thinking through hands-on projects.

FDM 3D Printing Materials Guide

Understanding filament types is essential for getting the best print results. Each material comes with strengths, weaknesses, and ideal applications.

A. PLA: Polylactic Acid

PLA is a beginner-friendly, biodegradable plastic made from corn starch. Makers love it for its low print temperature, minimal warping, and glossy finish.

Highlights:

Easy to print

Available in many colors

Suitable for display models and light-duty parts

Because it’s less durable than other materials, it’s not recommended for high-stress applications.

B. PET: Polyethylene Terephthalate

PET is known for its strength and moisture resistance. Many people choose it when they want functional prints that can withstand humidity.

Highlights:

Slightly flexible

Can be painted or post-processed

Ideal for food-safe or water-resistant parts

In addition, PET doesn’t release as many fumes during printing, making it safer indoors.

C. TPU: Thermoplastic Polyurethane

TPU is a flexible material that bends without breaking. People use it to make items that require durability and elasticity.

Highlights:

Highly flexible

Great for shock-absorbing parts

Withstands repeated bending

For example, TPU is perfect for making phone cases, shoe soles, or gaskets.

D. PC: Polycarbonate

PC offers unmatched strength. Engineers use it when parts need to tolerate high stress, impact, or heat.

Highlights:

Strong and heat-resistant

Durable in extreme environments

Excellent for functional prototypes

However, printing PC requires high temperatures and a stable build environment.

E. Nylon

Nylon is both strong and flexible. That’s why many industrial users rely on it for mechanical parts.

Highlights:

High tensile strength

Low friction

Tough and abrasion-resistant

Due to its water absorption, nylon needs to be stored carefully in dry environments.

F. ASA: Acrylonitrile Styrene Acrylate

ASA is a weather-resistant alternative to ABS. It resists sunlight, UV damage, and outdoor wear.

Highlights:

Doesn’t fade in sunlight

Operates from -65°C to 98°C

Long-lasting color retention

It’s widely used for outdoor signage, automotive parts, and enclosures.

Ready to Get Started? Let's Build Something Great Together!

Have a project in mind or need expert guidance? We’re just a message away. Click below to connect with our team — we’re here to help bring your vision to life with the right solutions tailored for your business.