Injection Molding

Injection Molding Services in Australia – Custom Plastic Solutions

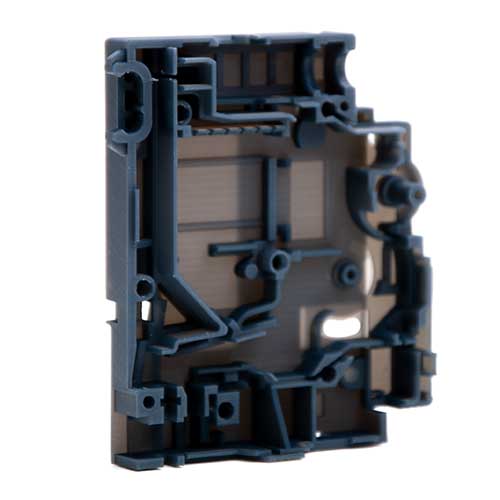

At Graphscape 3D, we offer high-quality injection molding services in Australia for producing durable custom plastic parts across industries like automotive, aerospace, medical, defense, and consumer products. Whether it’s low-volume prototyping or mass production, our advanced machines and skilled team ensure reliable results every time.

We manufacture a wide range of products including gears, brackets, knobs, and parts for vehicles, robots, toys, and more. Upload your CAD files online for an instant quote, and take advantage of our free design assistance to optimize your parts for rapid injection molding.

Our core injection molding processes include:

- Plastic Injection Molding – Producing strong, high-precision plastic parts using custom molds.

- Liquid Silicone Rubber Molding – Ideal for flexible, heat-resistant components with medical and industrial use.

- Overmolding & Insert Molding – Bonding materials like plastic over metal for stronger, more functional parts with reduced assembly.

Choose Graphscape 3D for reliable, cost-effective, and scalable plastic injection molding solutions in Australia.

Injection Molding Materials

We offer a broad selection of injection molding materials and can help you choose the right one for your needs:

Thermoplastics:

– ABS

– Acetal

– Nylon 6/6

– PEI (Ultem)

– PET

– Polyethylene

– Polypropylene

– Styrene (available in clear and opaque)

– TPE

– HDPE

– LCP

– PA (Nylon)

– Polycarbonate (PC)

– PMMA (Acrylic)

– POM (Acetal/Delrin)

Thermosets:

– Standard silicone (available in hardness from 30 to 70 durometers)

– Fluorosilicone (resistant to fuel and oil)

– Optical-grade silicone

– Medical-grade silicone

Precision:The accuracy of our products depends on factors like the material used, tooling, product design, and desired finish. Tolerances can range from ±0.2 to 0.5mm, with specialized applications achieving as low as ±5 µm. We can achieve surface finishes from 0.0500 to 0.1000 µm, with rough or pebbled textures also available.

Why Choose Foam Injection Molding?

Foam injection molding is an advanced low-pressure injection molding process that blends gas (like nitrogen or CO₂) with melted plastic to produce lightweight plastic parts with a solid outer shell and a cellular core. This method, also known as structural foam molding, is ideal for creating strong, durable components with reduced material weight and cost.It’s especially effective for large plastic parts with thick walls, offering faster cycle times, excellent dimensional stability, and cost-effective manufacturing for high-volume production.

Advantages of Foam Injection Molding:

- Lowers production costs

- Allows for complex designs

- Parts are stable and durable

- Uses less material, making it efficient and cost-effective.

Graphscape 3D is a top company in rubber and silicone molding, offering a wide range of molding services for various industries.

Surface Finishes & Benefits of Injection Molding at Graphscape 3D

At Graphscape 3D, we offer a wide range of injection molding surface finishes to suit your design and functionality needs:

- Glossy (A-grade) – Polished for smooth, shiny surfaces

- Semi-glossy (B-grade) – Matte finish using fine sandpaper

- Matte (C-grade) – Rough texture created with sanding stones

- Textured (D-grade) – Grit and glass beads provide a coarse, rugged finish

These finishes are applied directly through the mold, reducing the need for post-processing.

Why choose injection molding?

- Efficient, cost-effective plastic manufacturing for volumes of 10,000–25,000 units

- Low-waste production, with recyclable material use

- Ideal for high-precision, repeatable parts

- Supports complex geometries and fine details

- Minimal finishing required thanks to mold-based texturing

Graphscape 3D delivers reliable, scalable plastic injection molding solutions designed to meet both functional and aesthetic goals.

Ready to Get Started? Let's Build Something Great Together!

Have a project in mind or need expert guidance? We’re just a message away. Click below to connect with our team — we’re here to help bring your vision to life with the right solutions tailored for your business.